Suzhou Top Metal Materials Co.,Limited

We are professional metal materials manufacturer and supplier of steel materials like cold Rolled Steel, Galvanized steel, aluminum sheet, aluminum Grating Bar, aluminum perforated sheet, steel mesh, expanded metal, safety bar, Galvanized Metal Grating and wire mesh.

We partner with every customer and factories very close to control all processing details and our aim is to satisfy with our valuable customer.

We are open with OEM order and our customer are mostly from North America, South America, Western Europe, Eastern Europe, Eastern Asia, Southeast Asia, Middle East, Africa, Oceania,

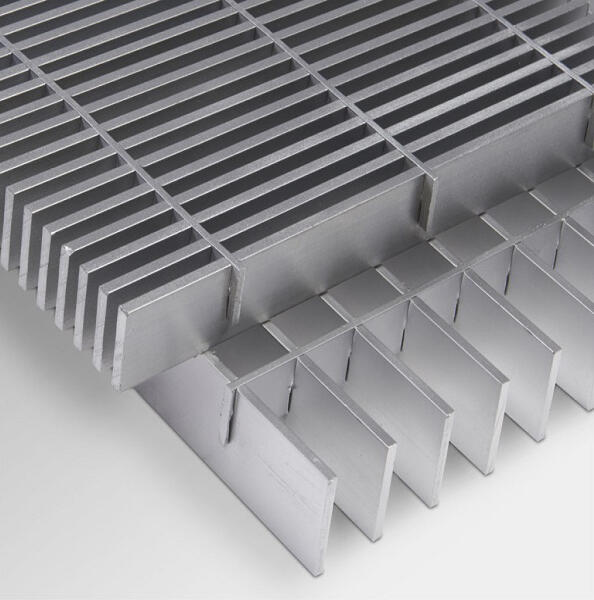

Aluminum Grating Bar Walkway

Aluminum grating bar is lightweight, corrosion resistant, and fully recyclable. With an unmatched strength-to-weight ratio, these products are ideal for both industrial and architectural applications. Manufactured from ASTM B221, 6063 or 6061 alloy or other steel materials.

6061 6063 Aluminum Bar Grating

Aluminum grating is an ideal choice when corrosion-resistant, lightweight materials that do not affect its load capacity and mechanical strength is required.Aluminum grating are generally available in four types: swaged rectangular aluminum grating, swaged I-bar aluminum grating, swaged flush-top aluminum grating, and dovetail pressure locked aluminum grating.

Aluminum Grating Walkway

Aluminum Bar Grating, also known as Swagged Aluminum Bar Grate is light weight, yet strong and durable for all load bearing applications that need high corrosion resistance. Aluminum Brating is available in a variety of bearing bar spacing, thicknesses and heights depending on applications and load requirements. Available in either smooth top or serrated for added slip resistance.

How to produce aluminum grating?

Arrange a plurality of punched aluminum strips ( load bar) at a certain distance, insert the aluminum square rod ( Cross Rod) into the arrranged load bar holes, press the part of the cross rod between the load bars to expand, tighten and fix the load bars, and form a grating plate together with the cross rods.

The load bar can be rectangular, I-shaped and T-shaped. 6061 and 6063- T6 aluminum alloy is the most commonly used materials for aluminum grating.

Aluminum grating is an ideal choice when corrosion-resistant, lightweight materials that do not affect its load capacity and mechanical strength is required. Made of ASTM B221, 6063 or 6061 alloy, aluminum grating has great versatile and durable and is mainly used for platform ceilings and outdoor curtain walls.

Aluminum bar grating is lighter than steel grating and has high load carrying capacity.

Aluminum gratings are made of aluminum alloy featured by cheap, economical and practical.

Smooth and serrated surfaces are available. Good anti-slip performance for safety protection.

Excellent corrosion and rust resistance for durability.

A variety of specifications and styles are available to meet various application environments.

Cross bars are fully locked within the bearing bars, slightly below the top surface. It has clean and crisp lines. With nearly 80% open area, it is commonly used in public areas and is the industry accepted standard for industrial applications. If anti-slip is required, swaged rectangular aluminum gratings with a serrated surface are available upon request.

Cross bars are permanently locked within the bearing bars to lock the pressure via unique extruded cross bars. Swaged flush-top aluminum grating provides an enhanced walking surface for areas subject to continuous pedestrian traffic. If anti-slip is required, we can provide swaged flush-top aluminum gratings with a serrated surface. It is mainly used for public areas.

Specification

Bearing bar size: 1″ x 1/8″ to 2–1/2″ x 3/16″ with 1/4″ increments;

Bearing bar spacing (center-to-center): 1–3/16″, 15/16″, 11/16″ and 7/16″;

Cross bar spacing (center-to-center): 4″ or 2″.

Supported by I-shaped extruded bearing bars, swaged I-bar aluminum grating carries the same load as the swaged rectangular aluminum grating with lighter weight and less costs. In addition, the striations at the top and bottom surfaces of the I bar increase the friction and provide high slip resistance performance.

Specification

Bearing bar size: 1″ x 1/4″ to 2–1/2″ x 1/4″ with 1/4″ increments;

Bearing bar spacing (center-to-center): 1–3/16″, 15/16″, 11/16″ and 7/16″;

cross bar spacing (center-to-center): 4″or 2″.

Pressure Locked Grating

Dovetail pressure locked aluminum grating is manufactured by inserting deep rectangular cross bars into pre-punched bearing bars to form an interlocking structure with strong lateral stability. Its neat appearance and tight spacing make it popular in architectural designs and is commonly used as sun shades and infill panels.

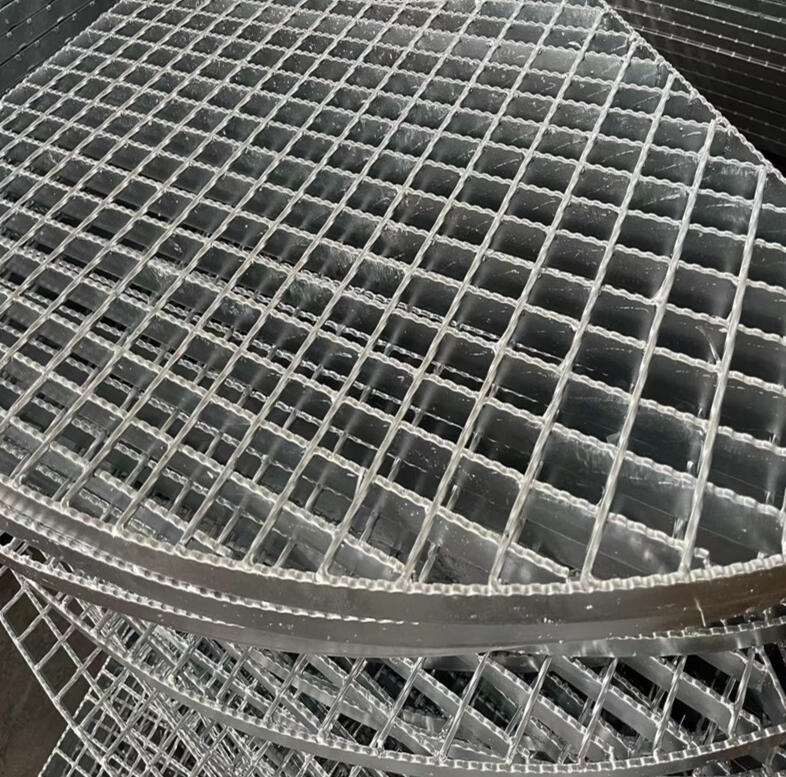

Heavy Duty Galvanized Steel Grating

Heavy Duty Steel Grating is manufactured by cross plain steel strips with the joint spot welded, 2mm thickness of steel strips as bearing and cross bars, then it is hot dip Zinc galvanized. This method provides a positive fusion of cross and bearing bars.

Different bearing bar thickness can be specified, the most common 1.8mm, 2.0mm with 30mm width and 10mm width.

Different thickness is offered to accommodate any load rating requirements. Universally used in most general industrial plants as well as commercial buildings; it has a wide range of uses such as walkways, platforms, safety barriers, ventilation grates, and drainage covers

Expanded Metal

3/4.125 expanded metal is formed by slitting and stretching process. With the characteristics of solid, durability and multipurpose, expanded metal mesh is widely used in every walk of life, especially the architecture and industry. Basically it includes raised and flattened two types

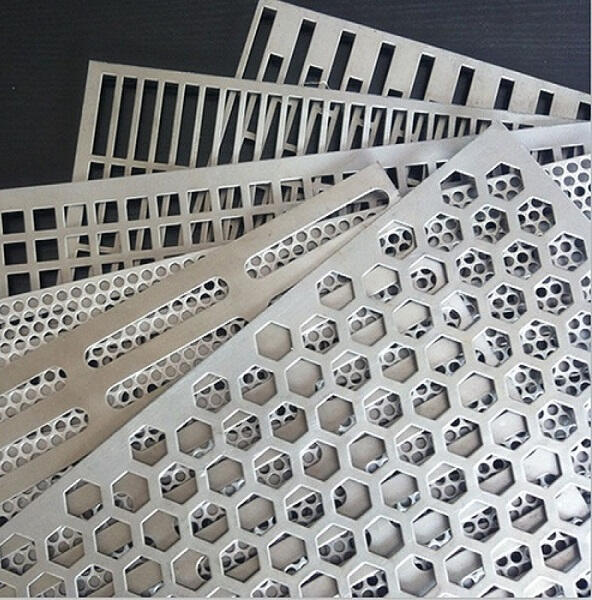

Perforated Sheet

Aluminum Perforated Sheet is lighter than both steel and stainless steel perforated sheet, while offering good corrosion resistance, weldability and formability. Aluminum perforated sheet is available with various hole size, staggers and sheet thickness.

Other Materials for perforated sheet are stainless steel, galvanized steel.

A perforated metal is sheet metal that has been stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes.

Contact

Suzhou Top Metal Materials is a supplier of steel materials like aluminum sheet, Aluminum strip, aluminum coils, aluminum plate, aluminum checkered plate and carbon steel plate. Top Metal Manufacture also sell cold rolled steel coils, SPCC, Galvanized steel sheet, SGCC, Galvalume steel coils, Aluzinc steel coils, prepainted Galvanized steel coil, PPGI and we can sell Non Grain oriented steel or CRNGO. We have products copper plate, alloy steel bar or Tungsten carbide materials available too.